Free Area of Wall Louvers

Every louver, no matter what size, has a calculated free area. By subtracting any obstructions to airflow (frames and blades) from the overall opening size we get a net result - free area. The typical size for louver comparison is 48" Wide x 48" High - which is an industry standard. Never assume that sizes other than this will have the same percentage free area.Free area varies widely by size, options (special shapes and screens), and louver model. Each of these has an impact on the free area and should be considered when selecting louvers for your application.

To ensure precise calculation of the free area, it is essential to use accurate measuring tools and consider best practices. Start by measuring the total area of the louver (height x width). It is important to open the louver to its fully open position (if applicable), to accurately assess the potential airflow. Next, identify and measure the area blocked by the louver’s frame, blades, or other components that may restrict airflow. These measurements are critical as they represent the physical limitations imposed by the louver design.

The standard formula for calculating louver free area then can be applied: Free Area = Total Louver Area - Airflow Restrictions. For example, if you have a louver that measures 2 feet by 2 feet, and it has obstructions totaling 2.2 square feet, the free area would be calculated as follows: Free Area = 4 square feet (total area) - 2.2 square feet (restrictions) = 1.8 square feet or approximately 45% of the total louver area.

By following these steps, you ensure that the calculation of the louver free area is both accurate and reflects the specific characteristics of the louver model and installation specifics.

Additional information on the impact of free area on louver selection, please visit the linked page how louvers work.

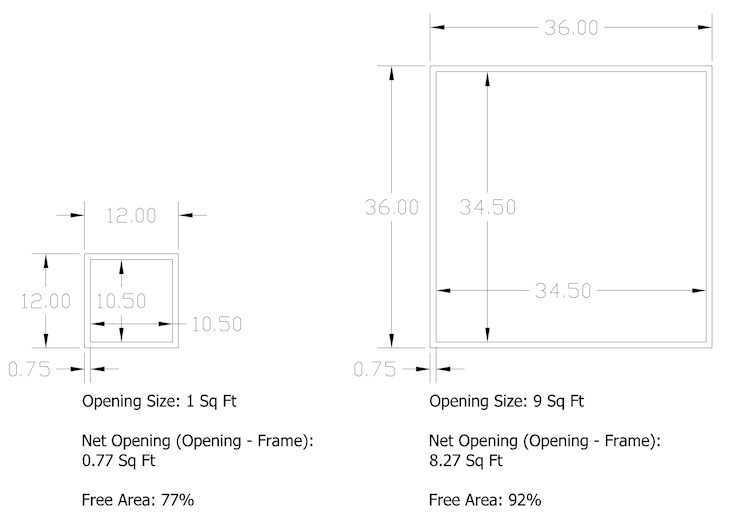

Size plays the most significant role in free area variation. Most people think of percentage free area as a constant, regardless of size. This is far from true, however. For example, the frame of the louver will take up more of the free area (as a percentage) as the louver size reduces (see Figure 1.1 below).

Even with a thin frame style (3/4" on all Architectural Louvers models) the percentage free area is significantly reduced on smaller size louvers. Keep in mind that we still need to subtract the blade obstruction from these numbers.

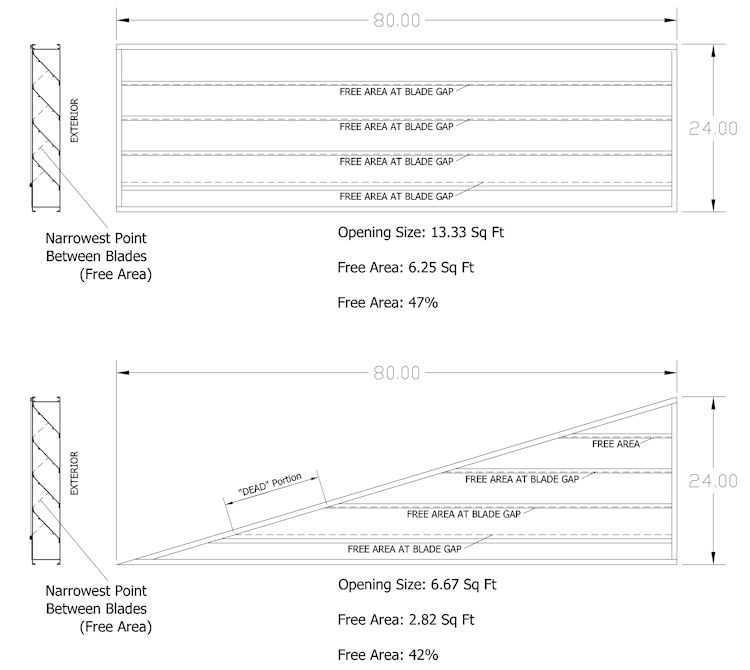

The shape of the louver will have an effect on the free area percentage. A slope or curvature eliminates some functional portion of each blade at the connection to frames, thereby reducing the free area. We have selected a comparison between a rectangular and triangular louver to demonstrate this reduction.

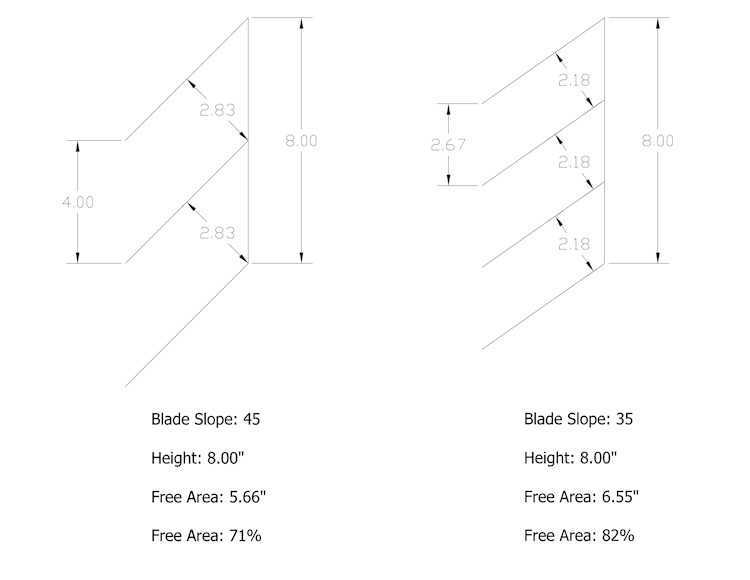

Because the blade is sloped from front to rear AND it is being mitered to fit flush to an adjoining frame, some of the free area is eliminated (the rear edge of each blade is shorter than the front edge). The angle slope of the blade and the pitch of the triangle will determine the free area reduction. As the slope of the blade increases (45 degree blade slope vs. 35 degree blade slope) or the pitch of the triangle decreases (3/12 pitch vs. 8/12 pitch), the "DEAD" portion of the blade increases, reducing the overall free area of the louver.

Many assumptions are made regarding rear screens on louvers. A very limited amount of industry testing has been done and the data is only relevant for new, clean screens. Dirty screens will eventually reduce the free area significantly.

In general, the free area of a louver is unaffected by a clean screen. AMCA (Air Movement and Control Association) tested and published results for the effect of screens on louver airflow and water penetration in their January 1994 Techspecs document. These tests demonstrated a slightly positive or negative effect on airflow through the louver (depending on the type of screen). Pressure loss increased 11% to 17%. Water performance improved 12% to 33%. But screens under airflow will eventually get embedded with dirt and grime, so most of the industry data is not relevant to real world application.

For small mesh screens (under 1/2" mesh) used at air intake locations, the buildup of dirt and grime can reduce the free area 10% to 90%. If left without maintenance, the screens will eventually block most of the airflow. If access to the screens is limited or maintenance is questionable, large mesh screen should be used.

Some good practices in screen selection:

- Air Ventilation only: any screen selection is acceptable.

- Air Intake (fan forced): Since the air in not yet filtered, the potential for accumulation of dirt and grime is high. Large opening bird screen (3/4") is the best choice. If any small mesh screen (1/2", 1/4", or insect screen) is desired for this application, a regular cleaning of the screen is required (once a month is recommended).

- Air Exhaust (fan forced): If the air has been filtered, any screen can be used. If small mesh screens are desired, a regular cleaning of the screens should be scheduled (twice a year). For unfiltered air, use the same precautions as Air Intake.

Every louver model has a different blade and blade spacing, so the free area will vary based on the characteristics inherent in that design. While free area is not the only consideration in selecting which louver to use, it can have a dramatic impact on performance.

In general, shallow slope blades allow for higher free areas based on simple trigonometry. To prohibit sight through between blades, the shallow slope will also require narrow blade spacing (more blades for the same height). This increases the cost of the louver.

Most commercial louvers have free areas between 30% and 60%. There are many residential style louvers that have free areas below 30%. Architectural Louvers makes many styles of louvers. The free areas are listed below:

Performance Table is based on a test size of 48" wide x 48" high for comparison purposes:

| Product Model | Free Area | First Point of Water Penetration (free area velocity) | Overall Performance (C.F.M.) | Pressure Loss at this velocity (inches water gauge) |

| E6JN | 69.1% | 915 fpm | 9014 cfm | 0.12 |

| E4DP | 59.3% | 930 fpm | 8826 cfm | 0.12 |

| E4JP | 58.4% | 960 fpm | 8976 cfm | 0.13 |

| E6DP | 57.7% | 1046 fpm | 9655 cfm | 0.13 |

| E6JP | 57.3% | 1123 fpm | 10298 cfm | 0.18 |

| E4DS | 56.0% | 930 fpm | 8333 cfm | 0.13 |

| E4WS | 56.0% | 346 fpm | 3100 cfm | 0.02 |

| E6JF | 54.4% | 1020 fpm | 8884 cfm | 0.18 |

| E2WV | 53.8% | 889 fpm | 7645 cfm | 0.24 |

| E6WH | 51.4% | >1250 fpm | 10275 cfm | 0.21 |

| E6WF | 51.1% | 1081 fpm | 8832 cfm | 0.14 |

| E4WH | 50.6% | >1250 fpm | 10113 cfm | 0.25 |

| E4JS | 50.4% | 888 fpm | 7157 cfm | 0.15 |

| E2DS | 49.4% | 889 fpm | 7032 cfm | 0.12 |

| E2JS | 48.7% | 725 fpm | 5648 cfm | 0.08 |

The significance of louver free area velocity in airflow efficiency lies in its impact on the functionality of the louvers. Higher velocities passing through louvers can lead to increased pressure drop and reduce the louver's ability to effectively prevent moisture from passing through. This underscores the importance of maintaining a lower airflow velocity to ensure that the louver can perform as intended. When comparing different louver designs, opting for the one with a greater louver free area is typically more advantageous in promoting optimal airflow efficiency.

Home How Louvers Work How Equipment Screens Work How Sunshades Work Wall Louver Applications Louver Free Area Hinged Louver Door Option Design Help Gallery Contact Us About Us Frequently Asked Questions Industry Links Privacy Policy Online Store